The future of transportation left Phoenix in the back of a truck last week.

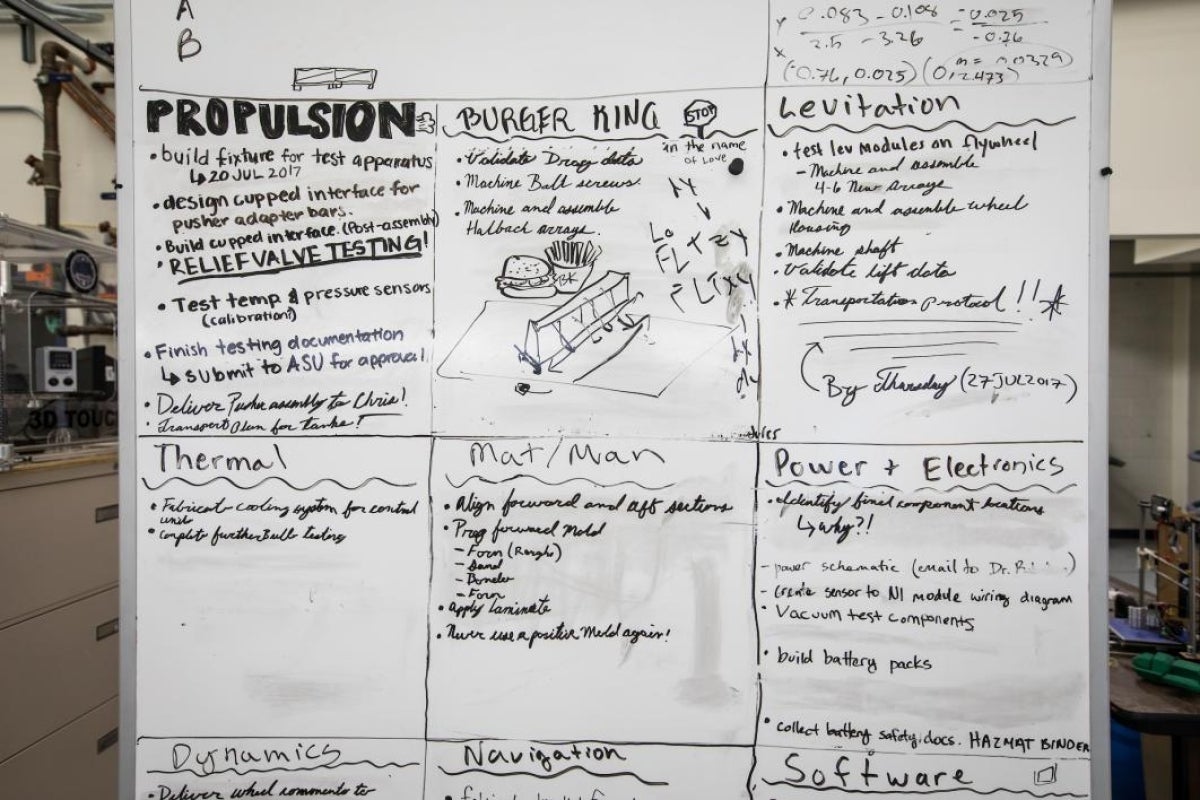

After two years of work, thousands of man-hours, almost $1 million, hundreds of pages of documentation and one baby, Arizona’s multicollegiate effort to build a hyperloop pod left for competition in California.

“Fastest pod to the end without crashing wins,” team co-lead Josh Kosar said.

The hyperloop is a high-speed mode of transportation envisioned by entrepreneur and SpaceX founder Elon Musk. If it comes to fruition, the result will be a pod traveling through a vacuum tube, without friction, at speeds up to 700 mph. A trip from Los Angeles to San Francisco would take 35 minutes to travel the 350-mile distance.

The Arizona team, made up of students from Arizona State University and its Thunderbird School of Global Management, Embry-Riddle Aeronautical University and Northern Arizona University, built and tested the pod at ASU’s Polytechnic campus.

AZLoop is one of 17 teams selected from a field of more than 1,000. The team is seeded second. Competition is slated for Sunday at SpaceX headquarters in Hawthorne, California.

“We’re fairly certain we’ll be running,” Kosar said.

Video by Ken Fagan/ASU Now

Not every generation gets to work on a completely new mode of transportation.

“It’s kind of unique,” Kosar said. “We’re having a lot of fun with it.”

As the time to competition neared, work and testing on the pod literally continued around the clock. Team members didn’t go home other than to shower. Students slept on couches and under tables as work continued around them.

The final assembly phase “is actually really difficult,” team co-lead Lynne Nethken said. “You plan and you have this idea in your head of how it’s going to go, and then you put bolt to wrench and for whatever reason it just doesn’t quite fit like it’s supposed to. Those are all the little things we’re working through right now.”

It has taken two years of work, including eight months with the full team of 120. All team members were required to work at least 10 hours per week. The core group put in about 30 hours each week; Kosar has worked on the pod for about 70 hours a week since October. (He also welcomed a baby boy into the world, factoring into the gray bags under his eyes.)

Co-lead Nethken has also been putting in 70 hours per week. “Just between the two of us, you’re up to thousands of hours,” Kosar said.

No one got away with resume stuffing. Kosar fired 160 students over the course of the project.

“It was hard at first,” he said. “It gets easier and easier.”

The pod, a sleek black bullet packed with electronics, batteries, magnets and wiring, cost just under $1 million to build. Funding came from in-kind donations, faculty members and the ASU Foundation. The Polytechnic School and the Ira A. Fulton Schools of Engineering heavily supported the project, Kosar said.

“These are the final weeks,” Nethken said. “No matter what we do or how hard we plan, there’s something called Murphy’s Law. In fact, the last week I always refer to as Murphy’s Law Week. Something will go wrong. It will throw off the plans. But that’s the importance of having this wonderful team we have. It doesn’t matter what it is. We’re going to figure it out, we’re going to tackle it, and we’re going to be ready to go when we ship out for final competition.”

They did the engineering and analysis, then moved into a production team. “We have to make this into one final unit, so our team needs to be one final unit,” Nethken said.

Documentation for the final design package ran at about 400 pages. Safety procedures were incorporated into a separate 150-page document submitted to SpaceX. The magnets used for levitation are so powerful they can crush fingers and break bones.

“We’ve had to outline all of those details so we make sure we’re doing so in a proper fashion that’s safe and efficient,” Nethken said.

Ernest Poteat is production manager. His job is to think 10 steps ahead and identify problems before they appear.

“It’s basically me running around like a chicken with its head cut off, trying to solve problems that aren’t there yet,” he said.

“As with any large group of people working on one project, there’s always the slight shortfalls or the little things here and there that nobody thought about or thought to think about, and we’re meeting those challenges and for the most part we’re exceeding them,” Poteat said. “We’re trying not to let that stuff stand in our way. As an overall assessment of the team, this is one of the finest teams I’ve ever worked with. I see us doing great things.”

“Every piece of this is because we made it happen,” Kosar said. “It’s definitely a team effort.”

Poteat said a lot of people are going to be surprised at the end of the day at what ASU is capable of.

“It’s a direct relationship between the people who are supporting us from the top, and the leadership that they’ve instilled here at this level,” he said. “It’s exciting. I’m interested to see where it’s going to go.”

Top photo: Members of the AZLoop team pose with the competition pod at the group’s 150-foot test track on ASU's Polytechnic campus in the pre-dawn hours of Friday, Aug. 18. Photo by Ken Fagan/ASU Now

More Science and technology

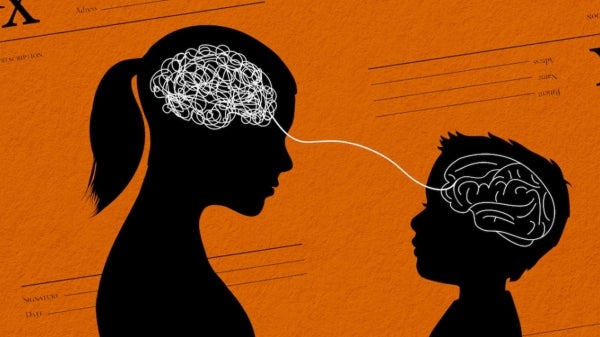

ASU postdoctoral researcher leads initiative to support graduate student mental health

Olivia Davis had firsthand experience with anxiety and OCD before she entered grad school. Then, during the pandemic and as a result of the growing pressures of the graduate school environment, she…

ASU graduate student researching interplay between family dynamics, ADHD

The symptoms of attention deficit hyperactivity disorder (ADHD) — which include daydreaming, making careless mistakes or taking risks, having a hard time resisting temptation, difficulty getting…

Will this antibiotic work? ASU scientists develop rapid bacterial tests

Bacteria multiply at an astonishing rate, sometimes doubling in number in under four minutes. Imagine a doctor faced with a patient showing severe signs of infection. As they sift through test…