Professor's new approach to manufacturing silicon could boost Arizona economy

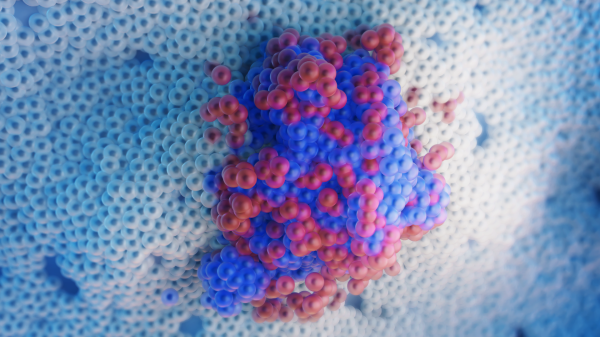

Assistant professor Bruno Azeredo's nanomanufacturing research focuses on the fabrication of silicon because of its potential use in 3-D microscale optical elements, such as the optical gratings used in microscopes and spectrophotometers that he is displaying above. Photographer: Jessica Hochreiter/ASU

Across Arizona and the U.S., advanced manufacturing propels economic growth.

In 2014, Arizona housed 157,000 manufacturing jobs and exported more than $22 billion in manufactured goods from Arizona-based defense, aerospace, electronics and optics industry companies, according to the Arizona Commerce Authority.

“Arizona is a key player in the manufacturing scene,” says Bruno Azeredo, a recently hired assistant professor in manufacturing engineering at Arizona State University.

With support from a $200,000 Science Foundation Arizona Bisgrove Scholar Award, Azeredo is leading a research project that aims to eliminate technical barriers that impose limitations on the productivity of manufacturing industries across the state.

In particular, he is addressing a major limitation in nanomanufacturing: the inability to pattern — or etch — 3-D features directly into silicon at the nanoscale level.

Azeredo is interested in the fabrication of silicon because of its potential use in 3-D microscale optical elements, such as lenses with unprecedented anti-reflective properties and diffraction gratings — for use in spectroscopic, telecommunications and laser applications.

But the cost of fabrication is a big inhibitor to the large-scale production and usage of these devices.

“Silicon 3-D patterning is currently very expensive and inaccessible for several commercial applications. If turned inexpensive, we could manufacture a novel set of optics materials with improved performance to be used in biosensing, silicon photonics and defense imagining systems,” says Azeredo.

In addition to high cost, the current methods for achieving these features are used successfully to pattern 2-D features, but don’t produce high enough resolution in 3-D.

Azeredo wants to overcome these limitations by automating a new manufacturing technique he invented, known as electrochemical imprinting.

This novel imprinting platform can directly pattern porous silicon and single-crystal silicon in a higher resolution (around sub-20 nanometers), and addresses key challenges that prevent scalable and low-cost processing of nanostructured silicon such as high defect density, low-dimensionality in geometrical control and low-throughput.

His method also relies solely on wet chemistry, bypassing the need for vacuum and cleanroom processing, which lowers the costs of semiconductor processing.

The benefits of this research could boast improvements in the performance of lithium-ion batteries, bio-imaging systems and bio-integrated electronics, micro-optical elements for silicon photonics and thermoelectric energy harvesting.

This project also has the potential to bridge the large gap between science and industry.

“If successful, manufacturing systems developed by this project can potentially eliminate barriers in the electronics, photonics and defense industries, all of which are strongly present in Arizona,” says Azeredo.

He hopes bringing this application into commercial development will help to grow the manufacturing of silicon in an economical and sustainable fashion.

Azeredo is the sixth faculty member in the Ira A. Fulton Schools of Engineering to earn a Bisgrove Scholars Award since the program was started in 2011 to recognize and support academics and researchers with the potential to transform ideas into technological advances that offer great value to society.

The transformative power of manufacturing engineering is exactly what sparked Azeredo’s initial interest in the field and also drives his continued commitment.

“Early on, I became fascinated with making structures and materials that the world has never produced before,” Azeredo says.

This led to his interest in the manufacturing processes employed in large-scale production of these structures, specifically in nanoscale smart materials and devices.

“What keeps me motivated is that the complex, 3-D structures I am learning to make and mass produce might have an impact in society,” he says.

It is a long road to make a hardware device, but as Azeredo says, “it all starts with a passion for manufacturing.”

More Science and technology

ASU and Deca Technologies selected to lead $100M SHIELD USA project to strengthen U.S. semiconductor packaging capabilities

The National Institute of Standards and Technology — part of the U.S. Department of Commerce — announced today that it plans to…

From food crops to cancer clinics: Lessons in extermination resistance

Just as crop-devouring insects evolve to resist pesticides, cancer cells can increase their lethality by developing resistance to…

ASU professor wins NIH Director’s New Innovator Award for research linking gene function to brain structure

Life experiences alter us in many ways, including how we act and our mental and physical health. What we go through can even…