The coolest moment in every science fiction flick is when the spacecraft takes off or lands, jets roaring, massive landing gear unfurling, claw feet flexing while debris flies in every direction.

But that last part — debris flying in every direction — is a problem in real life. High-velocity gases coming from rockets will create high-velocity projectiles flying from the surface of the moon. When we push out to settle the rest of the solar system, we’re going to need landing pads.

A spacecraft can kick up rocks as big as 3 feet wide and hurl debris — dirt, gravel, dust and rocks called ejecta in this context — everywhere. The Apollo 12 landing module sprayed ejecta as far as 500 feet away.

So landing pads are essential. What will they look like?

That was the subject of an expert panel discussion last week sponsored by Arizona State University’s Interplanetary Initiative.

The event was part of the Moon Dialogs, a series of lunar policy development workshops for subject matter experts in both space and terrestrial policy.

Ryan Watkins is a research scientist at the Planetary Science Institute. She specializes in landing site safety analysis and has been studying rocket exhaust effects for a decade.

“The general approach to plume effects is what is least bad?” she said. “Obviously we don’t want to damage our spacecraft or anything we’re landing close to.”

A spaceport won’t be needed for small one-off science missions or resource prospecting. But for commercial mining, human settlements or adventure travel, they’ll be a must.

Jeffrey Montes, a senior space architect at Blue Origin, created an architectural and conceptual design of four landing pads.

The big question right off the bat is: Where is it made, on Earth or on the moon?

If it’s made on the moon, what are you going to build it out of? “The moon is inherently scarce,” Montes understated.

Then how many features do you want? Just the basics or fully loaded?

“Without armoring the moon, you put the burden on armoring everything around the landing site,” Montes said.

He presented four models:

The Skinny

- It’s lightweight, imported and deployed on-surface. It has metal panels that unfold like a flower to reveal a bullseye in the middle of an apron of heat-resistant textile.

The Machine

- Also imported. With subsystems and landing gear, it’s a spacecraft unto itself. Elevated on legs, the exhaust duct redirects gas blast. It has a refueling arm and would be delivered as a lander payload or lowered via wire system.

The Brute

- Feature-poor but made on-site. It's a printed pad (additively constructed, high-temperature geopolymer made from silicon, oxygen, aluminum and iron, all found on the moon) mounted on a mound made from surrounding material, with an access road leading to the top.

The Works

- The most intricate of the bunch, this one will need full civil engineering. It’s an intricate multizone pad, an ejecta shield, and subterranean systems for refueling and capturing exhaust gases.

Montes designed to a 1-meter landing tolerance. Landers are going to have to have armored bottoms, and the engine can be configured to reduce or evenly distribute a blast load.

“The perfect solution probably lies somewhere in the middle of all of this,” Watkins said.

Phil Metzger, a planetary physicist at the University of Central Florida, was late to the discussion. He was helping pack a payload onto a rocket at the Mojave Spaceport.

Metzger did a study for NASA’s Jet Propulsion Laboratory last year on different landing pad technologies.

“I like Jeffrey’s approach that you build up capabilities over time,” Metzger said. “You don’t finish with what you started with.”

Happy landings.

Top illustration courtesy of NASA and Alex Davis/ASU Media Relations and Strategic Communications

More Science and technology

Damaged moon rocks persuade researchers to rethink lunar history

New research reveals that even lunar samples once believed to be pristine have been extensively altered by meteorite impacts, challenging long-held assumptions about the moon’s formation and early…

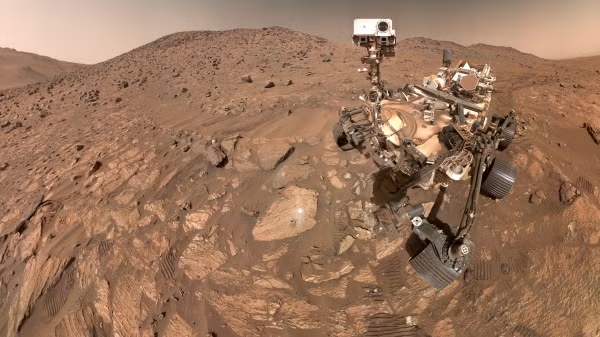

CSI: Mars

By Wendee NicoleTravelling to Mars has loomed large in the public’s imagination since at least the late 1800s when H.G. Wells' “War of the Worlds” tale of a Martian invasion was serialized in print.…

ASU research is helping solve crimes

On TV, detectives solve crimes in 43 minutes (plus commercial breaks). In real life, it takes much more time — and many more minds, including researchers discovering new ways to analyze evidence and…