Improving our ability to see in the dark through unique materials

As part of a U.S. Department of Defense Multidisciplinary University Research Initiative effort, Arizona State University Professor Yong-Hang Zhang will study the quality and stability of silicon-germanium-tin alloys and develop innovative device architectures for infrared applications. Photo by Erika Gronek/ASU

Brass, bronze and steel are metal alloys in which the combination of chemical elements — copper and zinc, copper and tin, iron and carbon, respectively — create unique properties, such as high strength and corrosion resistance, that can be used for particular purposes.

Arizona State University Professor Yong-Hang Zhang and Associate Professor Andrew Chizmeshya are exploring these purposes as part of a U.S. Department of Defense Multidisciplinary University Research Initiative effort. They will study the fundamental material properties of silicon-germanium-tin (SiGeSn) alloys for use in the next generation of lighter, faster and more energy-efficient infrared imaging technology.

The DOD MURI program supports multidisciplinary university research teams aiming to better understand or achieve fundamental research objectives that have never been done before. Many previous MURI projects have yielded significant breakthroughs, sustained scientific advancement and fostered the growth of graduate students in cutting-edge fields.

In 2019, the DOD issued 24 high-profile, highly competitive MURI awards totaling $169 million. Zhang and Chizmeshya will receive approximately $2 million of a $7.5 million MURI award shared with the lead institution University of Arkansas at Fayetteville and collaborators at Dartmouth University, the University of Massachusetts, Boston and George Washington University.

“The MURI program is one of the most competitive and most exciting programs from the DOD for university professors,” said Zhang, a professor of electrical engineering in the School of Electrical, Computer and Energy Engineering, one of the six Ira A. Fulton Schools of Engineering, and the director of ASU’s Center for Photonics Innovation. “This is my fourth MURI award related to semiconductor optoelectronic materials and devices, a clear indication of ASU’s strength in photonics research. We’re tackling a very challenging problem, so now we need to roll up our sleeves and get to work.”

The next generation of infrared imaging technology

Semiconductor materials — an essential component of electronic technologies such as lasers, solar cells and transistors — dominate the infrared imaging industry.

Current state-of-the-art infrared technology made with semiconductor alloys of mercury-cadmium-telluride, or elements from groups three and five in the periodic table, gives users the ability to see in both daylight and darkness and plays a critical role in U.S. military defense systems and commercial applications.

While infrared devices have significant potential to increase visibility across multiple platforms, current technologies that use semiconductor alloys are limited in performance by complex manufacturing operations, inefficient production processes, poor uniformity and high fabrication costs. These limitations hinder widespread use of the technology in military and civilian sectors.

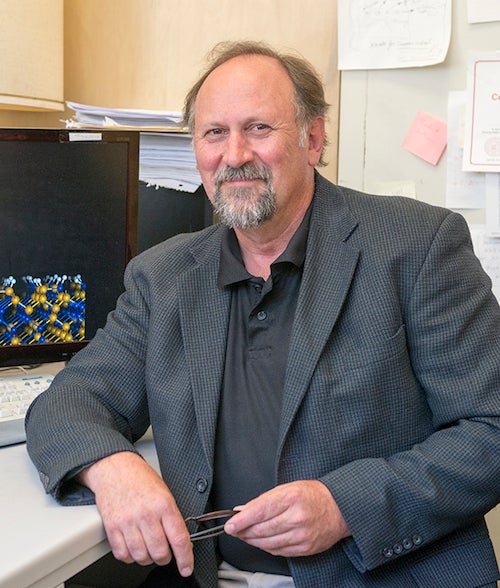

Andrew Chizmeshya

“SiGeSn alloys are a relatively new class of semiconducting materials that will allow the development of the next generation of high-speed detectors, emitters and modulators for applications in optoelectronic telecommunications and night vision,” said Chizmeshya, an associate professor of chemistry in ASU’s School of Molecular Sciences. “They are mostly composed of germanium, but the judicious addition of silicon and tin allows new electronic behavior, such as direct band gap, to be accessed.”

Similar to laying bricks to build a wall, researchers can add consecutive layers of semiconducting materials to fabricate a working device, like a cell phone chip. SiGeSn alloys allow multiple layers to be fabricated coherently leading to new semiconductor architectures with previously unattainable properties, such as achieving the longest range of infrared detection.

“If we can improve the SiGeSn material and put it on a silicon substrate with very large-scale integration, the whole system can outperform all current infrared technology at very low costs,” Zhang said. “It can enable people to see infrared — something human eyes do not see.”

To design, fabricate and demonstrate SiGeSn as the new semiconductor alternative for infrared technology, the MURI team has to overcome a range of material challenges. How do they reach middle-wave infrared wavelengths? Once achieved, how do they improve the material’s performance? When the SiGeSn material system exhibits quality and stability, how can they use it to make high-performance devices?

Additionally, Chizmeshya says thermodynamic data on SiGeSn alloys is exceedingly scarce. So, the research team will develop and apply a specialized, ground-up thermodynamic framework to shed new light on the origins of alloy stability and ultimately map out a phase diagram for the SiGeSn systems. The methodology could later be applied to other complex alloy systems.

If the project is successful, low-cost and high-performance infrared technologies with SiGeSn will have a tremendous impact for the U.S. Department of Defense. For instance, aircraft can be equipped with more efficient and cost-effective thermal infrared imaging to improve battlefield surveillance in poor visibility conditions. Additionally, soldiers and defense vehicles can be armed with ground-based vision systems to detect threats and vulnerabilities with higher accuracy and precision.

The effect of using SiGeSn alloys will reach well beyond the defense applications. Infrared technology can benefit medical care, surveillance, search and rescue applications, self-driving vehicles, meteorology and climatology.

Zhang envisions low-cost night vision technologies based on SiGeSn will be widely used by cars, trucks and other autonomous vehicles in less than 10 years. Car accidents due to limited visibility at night, in fog or in dust storms will be significantly reduced, saving lives and improving safety.

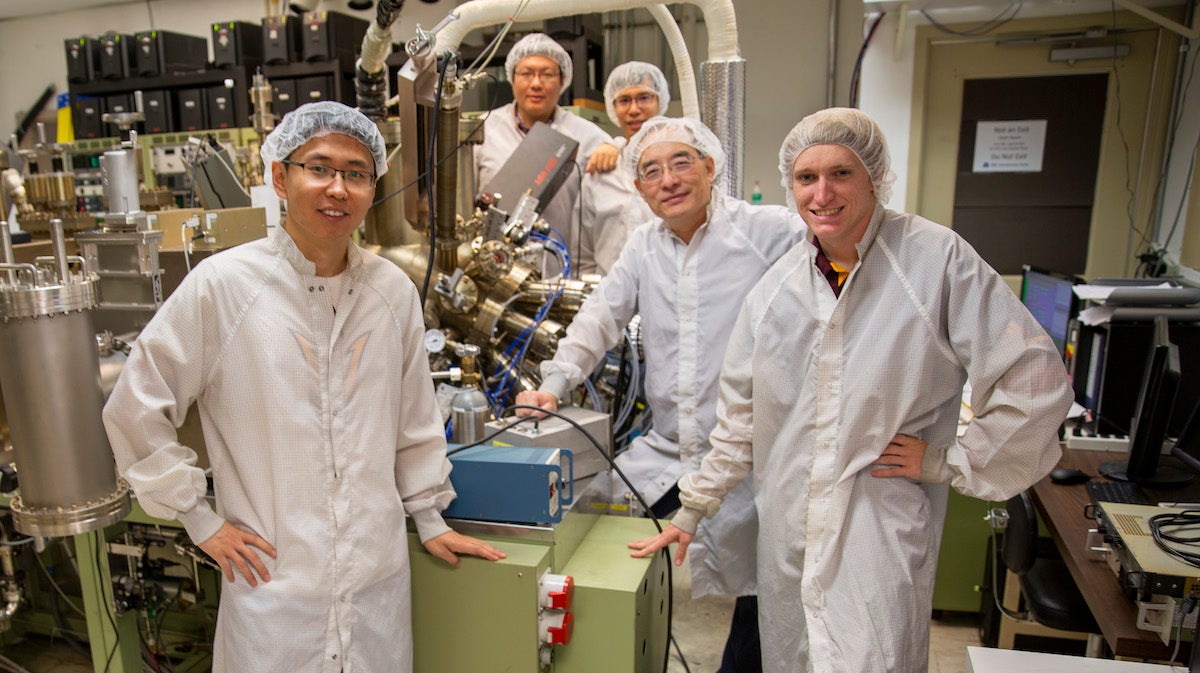

Under the mentorship of Professor Yong-Hang Zhang, Tyler McCarthy (left), an electrical engineering doctoral student, and Zheng Ju, a physics doctoral student, operate a molecular-beam epitaxy machine to grow single-crystal semiconductor thin films and solar cells. Photo by Erika Gronek/ASU

More than a decade of SiGeSn alloy expertise

This MURI Award brings together a multidisciplinary research team working at the frontier of SiGeSn alloys. The team of chemists, civil engineers, electrical engineers, mathematicians and physicists will leverage and build upon years of experience with infrared photonics research to understand fundamental material and device problems for SiGeSn and their low-cost, large-scale manufacturing.

Shui-Qing "Fisher" Yu, the principal investigator at the University of Arkansas, has expertise in the development of optoelectronic devices with SiGeSn alloys, such as lasers, photodetectors and infrared cameras. He also studies the potential of SiGeSn to improve materials quality and decrease costs for the devices.

Yu graduated from ASU with a doctoral degree in electrical engineering in 2005, earning the prestigious Fulton Schools Palais Outstanding Doctoral Student Award for his work in Zhang’s research group.

Zhang’s research has covered a broad area of optoelectronics, including the growth of semiconductor materials and their structural and optical properties, as well as novel semiconductor device design, fabrication and testing.

For this project, Zhang will seek a better understanding of epitaxial growth techniques, determine the quality and stability of the SiGeSn material and develop innovative device architectures tailored for SiGeSn alloys for infrared applications. Zhang’s expertise as an experimentalist pairs nicely with that of his collaborator and theorist Chizmeshya.

Chizmeshya’s expertise in theoretical solid-state electronics, chemistry and materials science methods will guide the design of new alloys and elucidate their thermodynamic, electronic and structural properties. He’ll use quantum-mechanics-based simulations to study key aspects of the chemical vapor deposition growth process using supercomputers.

“Many of the investigators on this MURI award have worked together and/or separately on various aspects of SiGeSn alloys for more than a decade,” Chizmeshya said. “We will be able to combine our individual expertise and vast collective experience for the first time.”

Professor Yong-Hang Zhang and his doctoral students in Arizona State University’s MBE Optoelectronics Group. Pictured from left to right: Jia Ding, Zheng Ju, Cheng-Ying Tsai, Zhang and Tyler McCarthy. Photo by Erika Gronek/ASU

More Science and technology

ASU and Deca Technologies selected to lead $100M SHIELD USA project to strengthen U.S. semiconductor packaging capabilities

The National Institute of Standards and Technology — part of the U.S. Department of Commerce — announced today that it plans to…

From food crops to cancer clinics: Lessons in extermination resistance

Just as crop-devouring insects evolve to resist pesticides, cancer cells can increase their lethality by developing resistance to…

ASU professor wins NIH Director’s New Innovator Award for research linking gene function to brain structure

Life experiences alter us in many ways, including how we act and our mental and physical health. What we go through can even…